Thermal management of aviation batteries: Dual improvement of safety and performance

introduction

existeVTOL (Electric vertical takeoff and landing aircraft) In the field of industrial drones, Lithium batteries are a key source of power driving advancements in flight technology. however, The battery is discharged at high rate, Risks such as thermal runaway are prone to occur under complex environmental changes, Therefore, thermal management systems have become essential for ensuring the safety of aircraft, The core link between performance and lifespan.

Why is battery thermal management crucial?

: security guarantee

The thermal management system can effectively control local overheating, Reduce the risk of thermal runaway, It's drones andeVTOLImportant conditions for obtaining airworthiness certification.

: performance optimization

Maintain at20–40℃The ideal working temperature range, Can extend battery life, Improve energy efficiency and flight endurance.

: system reliability

coordinateBMSReal time monitoring of temperature and current, Realize intelligent protection and fault warning.

Challenges faced by aviation thermal management

1. Thermal load under high rate discharge

Rapid discharge during takeoff and landing may cause instantaneous high temperatures, Efficient heat dissipation design is required to avoid malfunctions.

2. Lightweight requirements

Although the liquid cooling system has superior performance, But increase the weight; The air cooling system is lightweight, but its efficiency decreases when it is stationary.

3. Environmental adaptability

Drones are often needed in-10℃arrive50℃Temperature difference, Working in an environment with large changes in atmospheric pressure difference.

Innovative Solutions: Structural Optimization and Intelligent Control

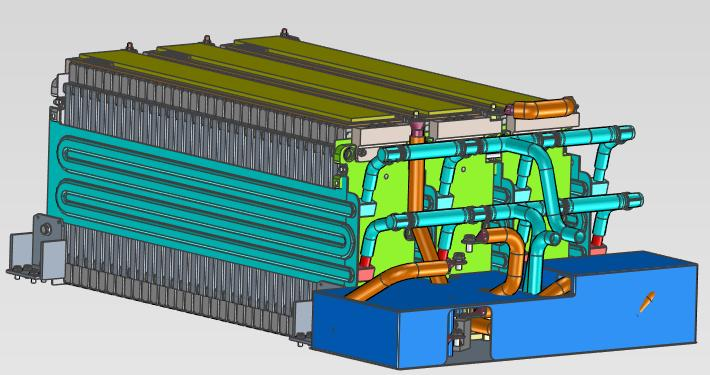

1. Composite heat dissipation technology

o Natural convection air cooling is used during flight, Reduce weight and energy consumption

o Introduce liquid cooling module during ground charging, Improve cooling efficiency

o Filling phase change materials between modules, Absorb instantaneous heat, Slow down the propagation of thermal waves

2. Airflow guidance and microchannel structure

o useZCombination of type air duct and microchannel, Make the airflow distribution more uniform

o Dynamic spoiler design enhances heat dissipation capability, Especially suitable for hovering scenes

3. intelligenceBMSintegration

o Real time evaluation through algorithmsSOC, SOHAnd heat dissipation requirements

o Support redundant control system, Enhance flight safety level

Commercial application cases

: certaineVTOLThe manufacturer adopts a composite cooling system

In high rate discharge testing, The peak temperature is effectively controlled within the ideal range, Improved cycle life and endurance performance.

: The drone platform adopts microchannel air cooling

Demonstrated superior heat dissipation efficiency and structural reliability in long endurance missions.

Future Trends: Integration of materials and algorithms

: New Thermal Conductive Materials

Including graphene composites, Liquid metal interface material, Having higher thermal conductivity and lower mass density.

: be based onAIThe Hot Wind Risk Prediction System

Utilizing data modeling and machine learning, Predicting potential thermal faults, Improve system adaptability.

conclusion

The thermal management technology of aviation batteries is in a rapid iteration stage. Moving from a single cooling technology to multi-mode integration, Moving from traditional passive temperature control toAIintelligent prediction, Opening up new imaginative space for the electric aircraft industry.

About Us

MindwayFocusing on high-performance drones andeVTOLPower Supply System, Having mature liquid cooling, Battery management and thermal simulation technology platform, Committed to promoting the safety and efficiency of electric aviation.

Email📫: market@mindwaytech. cn

WhatsApp📞: +86 18971062394